UNISORB® Solutions for the Metal-Forming Industry

UNISORB® Installation Solutions is the world leader in equipment installation systems and engineering, including those for the metal-forming industry. UNISORB® has the only Engineering Department devoted exclusively to the design andimplementation of complete machine installation systems. From the properly designedfoundation and isolation system to the installation system for the machine, UNISORB® will provide the most comprehensive package available.

Why Metal-Forming Machinery Needs UNISORB® Products

All too often in the metal-forming industry, presses are just set into place with little to no consideration for proper installation. When this vital aspect of press management is ignored, a variety of predictable problems occur, including excessive shock and vibration, internal press misalignment, and premature die wear, as well as press "walking" and other assorted difficulties.

At UNISORB® we understand that these problems often lead to expensive downtime and maintenance. To prevent this from occurring at your business, we offer a variety of high-quality mounting, installation, and press management products – seven, to be exact – designed to help you avoid the difficulties associated with improperly installed metal-forming machinery.

Installation Solutions

To install metal-forming machinery, working knowledge of machinery alignment, shock, and vibration control is required. An improperly installed metal-forming machines cause issues long-term and deplete profits.

To ensure you get the most from your machine, choose a professional installation by our Engineering Department. They will provide you with expert engineering designs and product selection so that your machine is as efficient and effective as possible.

If you experience shock or vibration with a current working machine in your plant, please contact UNISORB®. Our Engineering Department offers guidance in many areas; call us today!

For more information about machine installations, download this brochure:

Metal-Forming Machinery Solutions: Quantum PM™ Press Mounts

At UNISORB® Installation Solutions, we have designed our new line of Quantum PM™ Press Mounts to meet the installation and mounting needs for virtually any press built. From smaller tonnage presses to larger transfer presses in excess of 3,000 tons capacity, our Quantum press mounts will provide an ideal installation.

Learn more UNISORB's® Quantum PM™ Press Mounts by downloading this brochure:

UNISORB® Quantum PM™ Press Mounts General Catalog Information (PDF)

Benefits of Quantum PM™ Press Mounts

- Increased press life

- Increased tooling life

- Simplified press installation

- Fast, accurate alignment

- Reduced shock and vibration

- Elimination of anchor bolts

- Reduced need for special foundations

- Reduced motor loads

- Uneven floors accommodated

- Press "walking" prevented

Metal-Forming Machinery Solutions: Red-Line® Pads & Red- Line® Anchor Pads

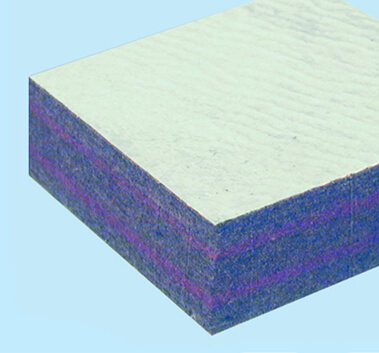

Our job engineered Red-Line® Anchor Pads substantially reduce vibration and noise ransmission. Available in a variety of densities and thicknesses to fit machine load requirements, UNISORB® Red-Line® Anchor Pads provide effective, low-cost vibration control for machinery.

Learn more about UNISORB's® Red-Line® Pads by downloading our additional resources:

Why Choose Red-Line® Anchor Pads?

Reduced vibration contributes to more efficient operation and longer life of costly machinery. Job-engineered Red- Line® Anchor Pads substantially reduce vibration transmission and keep light- and medium-duty machines from "creeping" or "walking" without the use of anchor bolts and will materially reduce transmitted noise. Installations are fast, easy, and inexpensive.

Metal-Forming Machinery Solutions: Titan™ Shock Pads

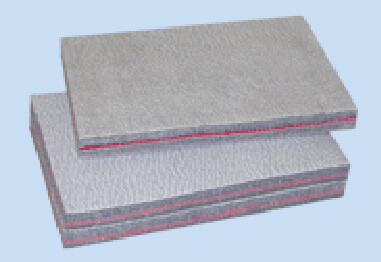

Titan™ Shock Pads offer an easy, economical way to solve problems associated with impact, shock, and vibration, which can cause costly damage to machines, mounting devices and floors. These tough, textile- and neoprene-laminated pads are ideal for installations with extreme loadings or heavy impact.

Learn more UNISORB® Titan™ Shock Pads by downloading additional resources:

Typical Applications for Titan™ Shock Pads

Regufoam® vibrationplus is an engineered combination closed and open cell foam material that exhibits excellent vibration isolation characteristics including exceptional damping and superior durability in the industrial/commercial environment as proven in over two decades of successful applications.

- Ball Mills

- Compressors

- Forging Hammers

- Heavy Presses

- Impact Generating Machine Shop Equipment

- Presses

- Pumps

- Structural Bearings

- Central Air Conditioning

- Foundry Equipment

- Generators

- Hydraulic Hammers

- Motors

- Printing Presses

- Refrigeration Equipment

- Textile Machinery

Metal-Forming Machinery Solutions: Die Turnover™ Pads

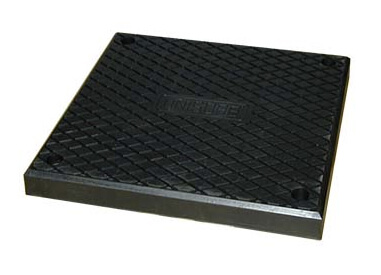

UNISORB® Die Turnover Pads™ are designed to replace creosote wood blocks or other flooring methods in die manufacture or repair areas. These simple and reliable resilient floor systems for die-handling areas come complete and ready to install, requiring no maintenance.

Want more information about our Die Turnover™ Pads? Download our helpful catalog:

UNISORB® Die Turnover™ Pads General Catalog Information (PDF)

Benefits of Die Turnover™ Pads

- Simple and cost effective means of providing a resilient work surface that eliminates handling damage to precision dies

- Complete, ready to install, requiring no maintenance (anchoring kits are available)

- Capable of withstanding continuous heavy traffic and extreme loads imposed by the heaviest dies

- Precision molded 80 durometer neoprene

- Heavy steel backing plate to facilitate anchoring

- High friction texture and self-draining diamond surface pattern

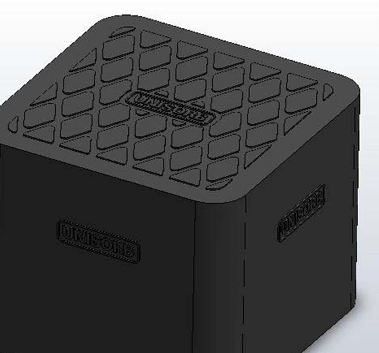

Metal-Forming Machinery Solutions: IB-500™ Inertia Block

Foundation Isolation Materials

Engineered to provide optimum compression rates for the inertia block while using standard foundation construction techniques, the UNISORB® IB-500™ Inertia Block Isolation Materials provide superior performance. The materials are manufactured in two densities, are available from stock in 3' x 6' sheets for fast delivery, and special sizes can be cut to exact dimensions at the factory or on the job site.

Learn more UNISORB's® IB-500™ Inertia Block Isolation Materials by downloading additional resources:

UNISORB® IB-500™ Inertia Block Isolation Materials Information (PDF)

UNISORB® IB-500™ Inertia Block Isolation Materials Safety Letter (PDF)

Isolate Vibrations with IB-500™

IB-500™ isolation pads are designed to employ standard foundation construction techniques to isolate vibrations typical to the manufacturing environment.

Metal-Forming Machinery Solutions: Regufoam® Vibrationplus

Applied as a vibration-isolating structural element in the installation of both source and sensitive equipment, Regufoam® provides a cost-effective and simple approach to preventing the transmission of structure-born noise and vibration. The product is available in thicknesses of 25mm or 50mm, and is available in four basic color-coded densities.

For additional information regarding UNISORB’s Regufoam® Vibrationplus for vibration isolation, please download the following helpful PDFs:

Stop Structure-Borne Noise and Vibration

- Natural Frequency Range of 7 - 15 Hz.

- Proven Long Life

- Simple Installation

- Exceptional Damping

- Superior Durability

Metal-Forming Machinery Solutions: GK™ Low-Frequency Foundation Blocks

This product is specifically used for isolating equipment where low interfering frequencies are encountered. The highly specialized rubber compounds used, unique geometrical shape and carefully controlled load deflection characteristics make the GK™ Low-Frequency Foundation Block an affordable alternative to installations normally required to reach system natural frequencies as low as 4 Hz.

Want more information? Download our helpful information regarding UNISORB's® GK™ Low Frequency Foundation Block: UNISORB®

UNISORB® GK™ Low Frequency Foundation Block Product Information (PDF)

Examples of GK Block™ Applications

- Coordinate Measuring Machines

- Precision Optical Equipment

- Precision Grinders

- Vibrating Conveyors

- Lab Equipment

- Presses

The GK Block™ is commonly used for equipment operating in environments of unusually severe shock and vibration conditions.

Contact UNISORB®

Reach UNISORB®’s Engineering Department via phone, email, or through our online contact form below.