UNISORB® Solutions for Power Generation Installations

Since 1982, UNISORB® has been a supplier of anchoring/alignment systems, leveling devices, and grouting materials for steam turbine installations. Our strong background in this field, coupled with our successful track record, positions us as a leader in the industry. Our experience pertinent to this field includes power generation, process, and manufacturing.

UNISORB® supplies equipment for power generation installations in kit form. These kits are designed and furnished for each specific machine application. They include all the necessary hardware and support materials for a complete and successful installation, also includes a set of engineering drawings to provide field staff with the necessary instructions to install a quality mounting system.

Why Wind & Steam Turbines Need UNISORB® Products

Power Generation installations are unique. Usually these installations are difficult and require a huge amount of labor and many days to complete. Power generation installations also become complicated quite quickly, requiring multiple source and component quotes, adding to the amount of time to complete these installations.

Wind or steam turbine installs require sophisticated designs including foundation layout, which can be complex. In addition, many power generation installs are not handled correctly, and thus require much rework and cause delays.

Installation Solutions

By using a UNISORB® installation kit specifically for wind turbines, you'll save a massive amount of time. When you save time on installation, you also save money. Our clients have saved significant amounts of time by using our kits. In fact, some of our power generation clients have achieved time savings of up to 80%. This amounts to significant dollar savings.

How you save on labor time & costs:

Reduced Labor: Savings of 300 to 500 man hours on typical installations. Calendar savings of 9-14 days.

Reduced Project Management Labor Requirements: Uses one source for all material requirements. Multiple source and component quotes are eliminated. UNISORB® supplies materials to customer specifications.

Reduced Design Time: All embedments and grout pockets are designed. Foundation layout and component drawings are furnished and can be referenced on construction drawings.

Reduced Rework: Increased ability to deal with out of spec foundation and site preparation work; Costly rework and associated delays are eliminated

Learn more by downloading this brochure:

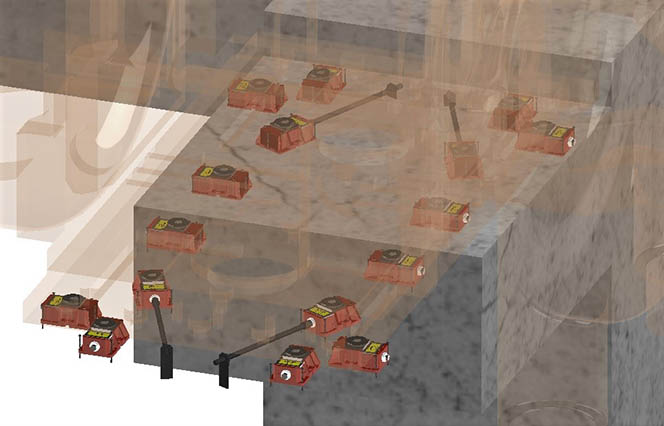

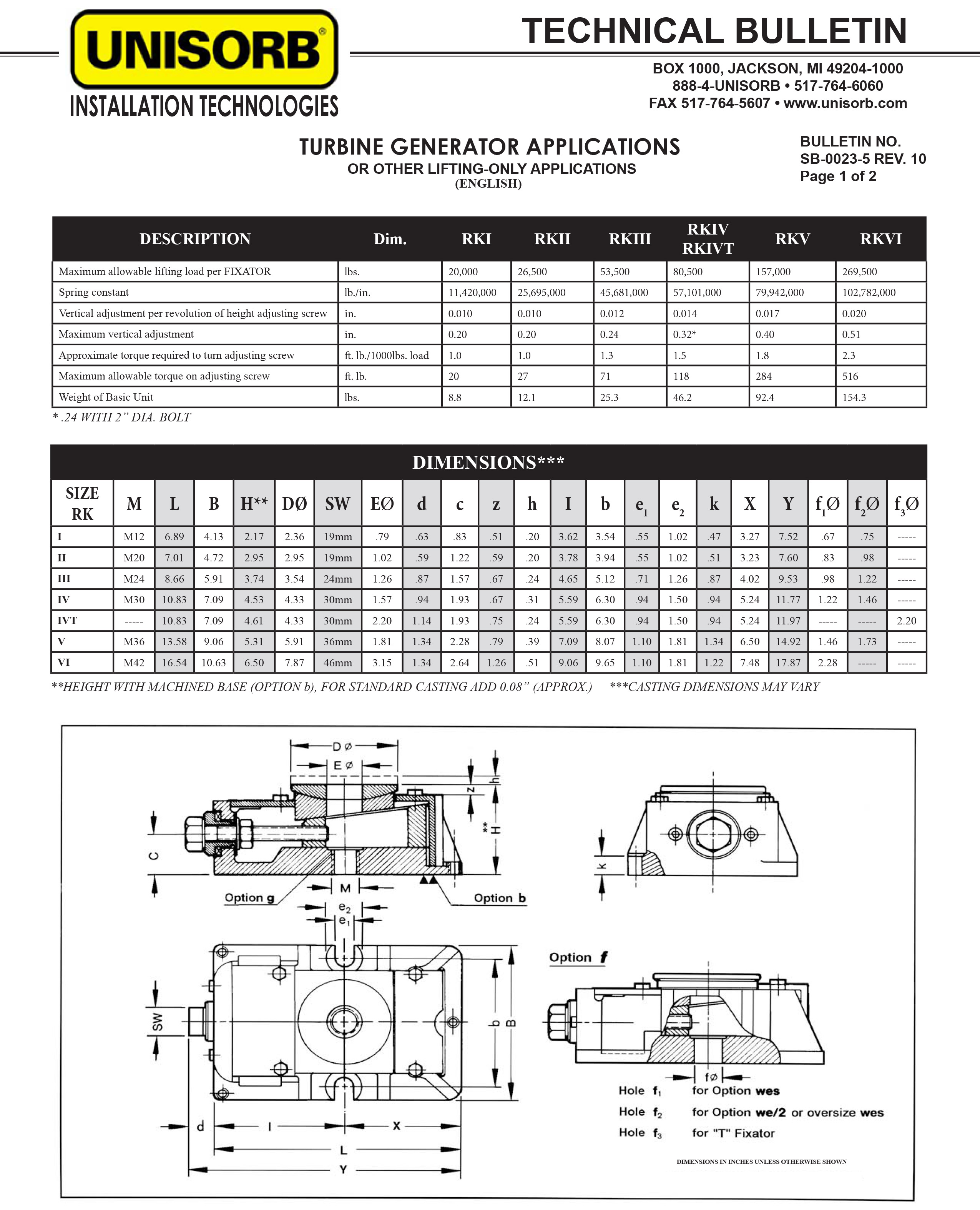

Power Generation Solutions: FIXATOR® System

For the most rigid machine-to-foundation connection available, use the UNISORB® FIXATOR® System. This innovative anchoring and alignment system is easily adapted to all types of power generation installations.

Learn more UNISORB's® FIXATOR® Systems by downloading this brochure:

Quick & Simple Installations & Realignments

The FIXATOR® System makes support-critical machinery installations fast and simple. Each application is engineered by our professional engineers to assure successful implementation and results.

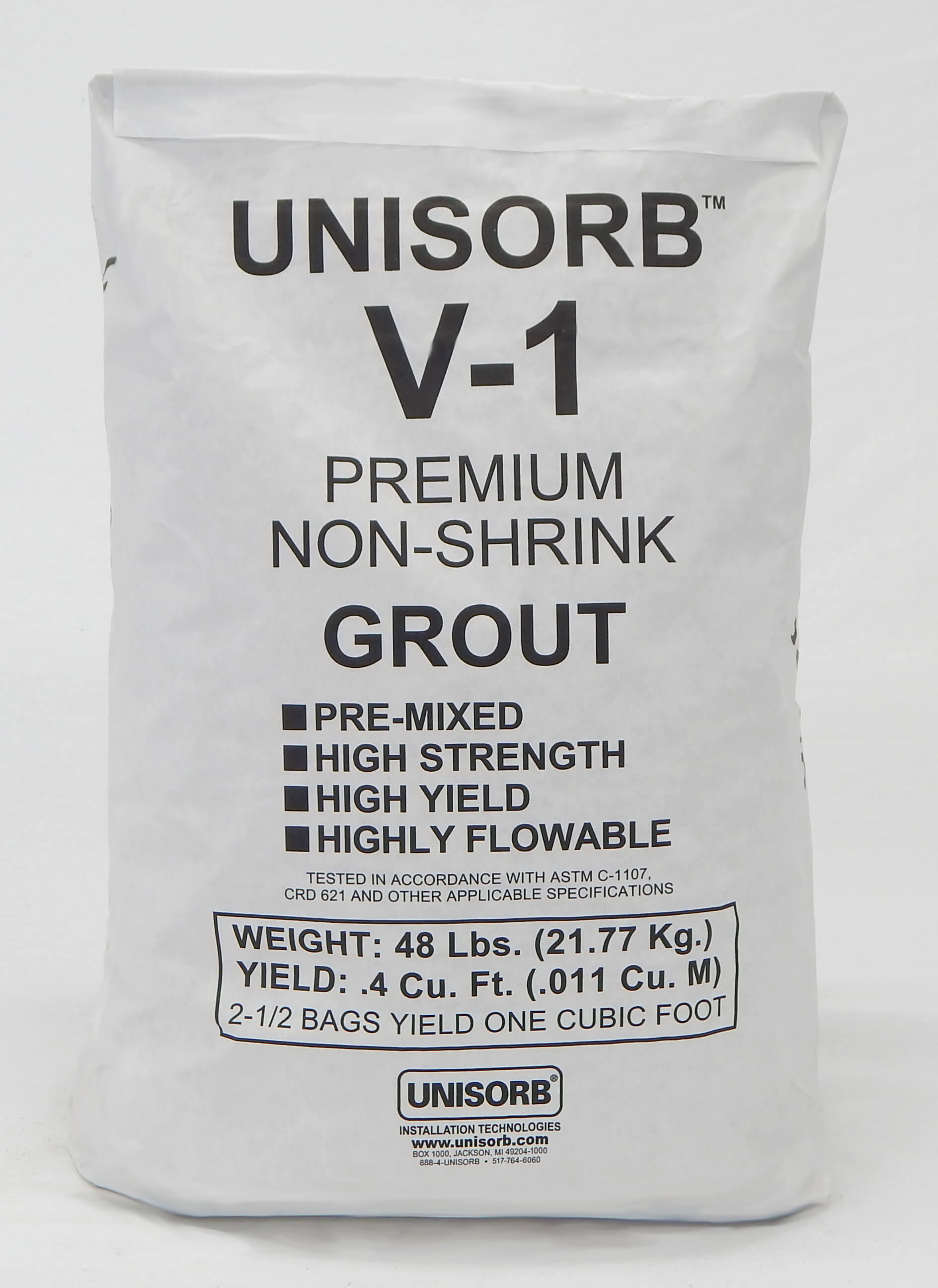

Power Generation Solutions: Cementitious Grouting Products

Careful development has resulted in a grouting material that provides optimum performance, even in the toughest applications. Our cementitious grouts also very easy to prepare and place.

Download our Grouting Products catalog (below) for answers to commonly asked questions, such as How long after a foundation is poured can grout be used?

Find out more about our grouting products by viewing our PDF:

Recommendations for Grouting Machinery

The goal of grouting machinery is to form a high-quality machine-to- foundation connection so that installation is successful. There are several things that affect a successful installation, including:

- Proper Grout Selection for Your Application

- Foundation Preparation

- Forming Method Employed

- Careful Attention to the Actual Application of the Grouting Material

A high-quality grouting installation is the key to successful machine installation. The time spent in thoroughly planning the installation will pay off in less maintenance requirements and higher productivity during the life of the machine.

Power Generation Solutions: V-100® Epoxy Grouts

Epoxy grout cures rapidly and offers a very strong bond, which less can be used. The epoxy grouts are made of a base resin and hardener that are mixed at the jobsite immediately before placement. Epoxy grout is able to withstand significantly higher shock loads than cementitious materials. Epoxies also can be used in much thinner cross sections than cementitious materials, which is excellent for certain applications.

Learn more UNISORB's® V-100® Epoxy Grouts by downloading these resources:

Epoxy Grouting Materials Available

- Standard V-100®

- Ship-Safe Standard V-100®

- Deep Pour V-100®

- Adhesive V-100®

- Low-Temp V-100®

- Acid Resistant (DCR) V-100®

- Hi-Flow (CR) V-100®

- Ship-Share Hi-Flow (CR) V-100®

- Joint Filler V-100®

- Hi-Temp V-100®

- Xtra-Temp V-100®

- WTF-E V-100®

Contact UNISORB®

Reach UNISORB®’s Engineering Department via phone, email, or through our online contact form below.